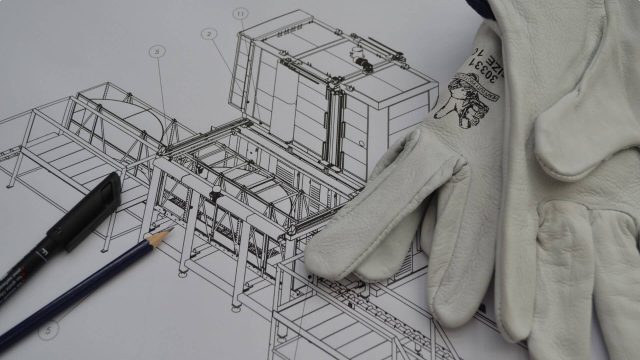

TK Chemical Tempering Kilns

Automatic oven for chemical tempering of glass

High-performance system for chemical tempering of glass

Chemical tempering of glass is obtained by immersing the material to be treated in a bath of molten potassium salts at temperatures above 400° C. The potassium ions (K+) contained in the salt replace the smaller diameter sodium ions (Na+) contained in the surface of the glass, causing compressive stresses to build up across the surface and edges.

The mechanical flexural strength properties of chemically toughened glass are five to ten times higher than those of thermally toughened glass subjected to the same force. This particular manufacturing process also increases impact resistance: thermally toughened glass has an impact resistance with a steel ball that is almost double that of standard float glass; but the impact resistance of chemically toughened glass is five times that of standard float glass, guaranteeing absolute flatness without any visual distortion.

All types of standard float glass can be chemically toughened. Green glass usually undergoes less ion exchange than the others. Coated glass and glass with a different chemical composition to standard float glass are not chemically toughenable. The parameters of the chemical tempering process may vary depending on the type of glass and the required specifications.

By means of chemical tempering, glass with a minimum thickness of 0.5 mm can be tempered. Even glass with a special geometrical shape can be chemically tempered, maintaining a high optical quality.

Technical specifications

- Electric heating

- Programmable touch screen operator panel

- Thick stainless steel salt tank

- Power failure safety system – UPS

- Pre-heating hood

- Electromechanical glass lifting system

- Maximum temperature 500° C

Areas of application

Request a personalised consultation

Would you like more information or to talk to a TK specialist? Contact us and we will provide you with all the assistance you need to design the most suitable oven for your needs.

Discover our services

TKonnect 4.0

The TKonnect 4.0 remote system allows real-time monitoring of the TK ovens’ production process via smartphone or computer, combining a new, fully intuitive user interface concept with the latest technology available.

TKare

H24 remote technical support from our team, designed for your training; access to machinery from anywhere without the need for any software, data connection – downloading production reports via the Internet from any type of device.

TKlean Bag

The innovative laminating vacuum bag that avoids edge cleaning in any glass laminating oven: TK has introduced TKlean Bag, which, in combination with STRATO® interlayers, enables a perfect edge finish and improved glass flatness after the laminating process.