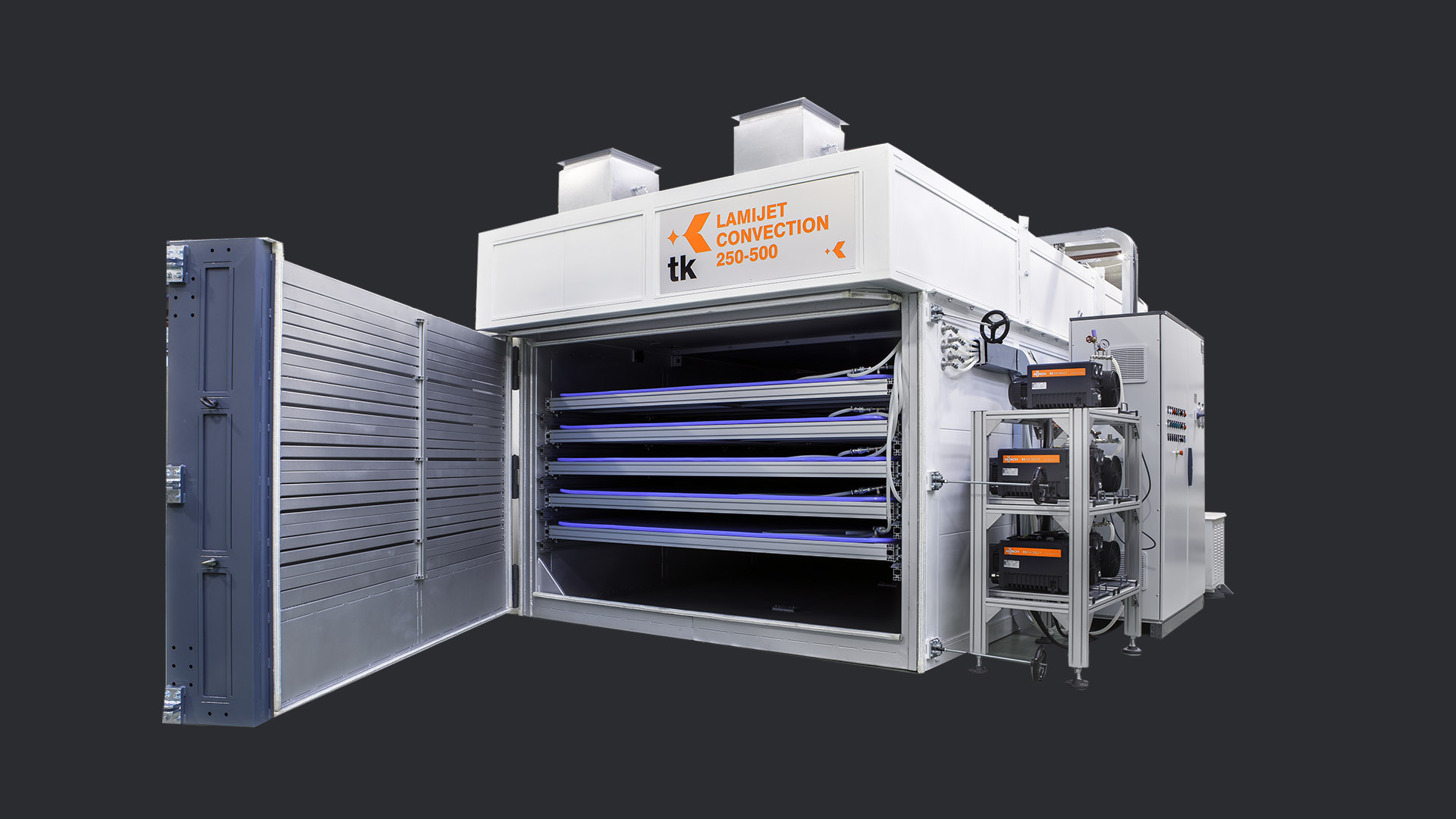

TK Convection

High-performance laminating oven

TK Convection: the best solution for handling high production volumes

Innovative laminating oven with rapid heating and cooling. Designed for high production volumes with reduced operating costs. Enables lamination of EVA, PVB, TPU and SGP, without the use of an autoclave.

The modular system allows quick and convenient loading of trolleys for lamination or HST processes.

- Reduced operating costs

- High production volumes

- Fast heating and cooling

Technical specifications

- Up to 6 floors

- TKonnect 4.0

- Real-time production analysis

- Rapid heating and forced rapid cooling

- Maximum temperature uniformity

- Autonomous temperature zones with automatic temperature control

- Intelligent heating system for low energy consumption

- Intelligent vacuum system that adapts to the requirements of the laminating interlayer

- Efficient silicone bags with Lock Seal quick closure system

The advantages of Lamijet Convection

Improve the quality of your work. Discover the entire line of TK accessories

Request a personalised consultation

Would you like more information or to talk to a TK specialist? Contact us and we will provide you with all the assistance you need to design the most suitable oven for your needs.

Discover our services

TKonnect 4.0

The TKonnect 4.0 remote system allows real-time monitoring of the TK ovens’ production process via smartphone or computer, combining a new, fully intuitive user interface concept with the latest technology available.

TKare

H24 remote technical support from our team, designed for your training; access to machinery from anywhere without the need for any software, data connection – downloading production reports via the Internet from any type of device.

TKlean Bag

The innovative laminating vacuum bag that avoids edge cleaning in any glass laminating oven: TK has introduced TKlean Bag, which, in combination with STRATO® interlayers, enables a perfect edge finish and improved glass flatness after the laminating process.